All About Investment Casting

What is Investment Casting?

Investment casting, also known as precision casting or lost-wax casting, is a manufacturing process in which a wax pattern is used to shape a disposable ceramic mold. A wax pattern is made in the exact shape of the item to be cast. This pattern is coated with a refractory ceramic material. Once the ceramic material is hardened, it is turned upside-down and heated until the wax melts and drains out. The hardened ceramic shell becomes an expendable investment mold. Molten metal is poured into the mold and is left to cool. The metal casting is then broken from the spent mold.

The term investment casting is derived from the process of “investing” (surrounding) a pattern with refractory materials. Investment casting is often selected over other molding methods because the resulting castings present fine detail and excellent as-cast surface finishes. They can also be cast with thin walls and complex internal passageways. Unlike sand casting, investment casting does not require a draft.

These process qualities can provide net shape or near-net shape castings, which provide customers with significant cost savings in material, labor, and machining. It can make use of most common metals, including aluminum, bronze, magnesium, carbon steel, and stainless steel. Parts manufactured with investment casting include turbine blades, medical equipment, firearm components, gears, jewelry, golf club heads, and many other machine components with complex geometry.

The main points of this article are as follows,

1.What is Investment Casting?

2.History of Investment Casting

3.How are Investment Castings Made?

4.Advantages and Disadvantages of Investment Casting Process

5.The application of Investment Casting

6.Investment Casting VS Die Casting

7.Investment Casting VS Sand Casting

History of Investment Casting

The history of lost-wax casting dates back thousands of years. Its earliest use was for idols, ornaments and jewelry, using natural beeswax for patterns, clay for the molds and manually operated bellows for stoking furnaces. Examples have been found across the world, such as in the Harappan Civilisation (2500–2000 BC) idols, Egypt's tombs of Tutankhamun (1333–1324 BC), Mesopotamia, Aztec and Mayan Mexico, and the Benin civilization in Africa where the process produced detailed artwork of copper, bronze, and gold.The earliest known text that describes the investment casting process (Schedule Diversarum Artium) was written around 1100 A.D. by Theophilus Presbyter, a monk who described various manufacturing processes, including the recipe for parchment. This book was used by sculptor and goldsmith Benvenuto Cellini (1500–1571), who detailed in his autobiography the investment casting process he used for the Perseus with the Head of Medusa sculpture that stands in the Loggia dei Lanzi in Florence, Italy.

Investment casting came into use as a modern industrial process in the late 19th century, when dentists began using it to make crowns and inlays, as described by Barnabas Frederick Philbrook of Council Bluffs, Iowa in 1897. Its use was accelerated by William H. Taggart of Chicago, whose 1907 paper described his development of a technique. He also formulated a wax pattern compound of excellent properties, developed an investment material, and invented an air-pressure casting machine.

In the 1940s, World War II increased the demand for precision net shape manufacturing and specialized alloys that could not be shaped by traditional methods, or that required too much machining. Industry turned to investment casting. After the war, its use spread to many commercial and industrial applications that used complex metal parts.

How are Investment Castings Made?

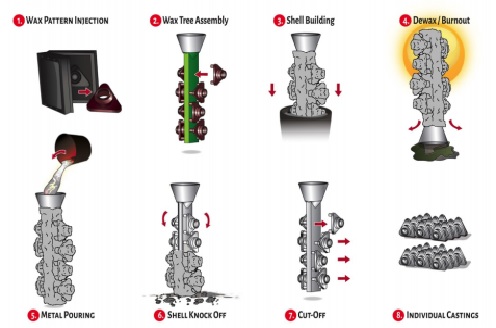

The investment casting process consists of 8 steps:

Creating a Wax Pattern

Wax Tree Assembly

Shell Building

Dewax / Burnout

Metal Pouring

Shell Knock Off

Cut Off

Individual Castings

1. Creating a Wax Pattern

• In today’s manufacturing world, wax patterns are typically made by injecting wax into a metal tool or “die”

• With the evolution of Additive Manufacturing, patterns can be printed

• In the art community, one of a kind pieces are carved by the artist from wax blocks

• For multiple castings, a silicon tool is usually made from the artist’s sculpture and wax is injected or poured into the resulting cavity.

2. Wax Tree Assembly

• It is typically uneconomical to make small parts one at a time, so wax patterns are typically attached to a wax “sprue”• The sprue serves two purposes 1. It provides a mounting surface to assemble multiple patterns into a single mold, which will be later filled with alloy. 2. Provides a flow path for the molten alloy into the void created by the wax pattern(s)

• The wax between the pattern(s) and the sprue is called “Gates”, because they throttle the direction and flow of the alloy into the void made by the pattern.

3. Shell Building

• The next step in the process is to build a ceramic shell around the wax tree• This shell will eventually become the mold that metal is poured into

• To build the shell, the tree is dipped into a ceramic bath or “slurry”

• After dipping, fine sand or “stucco” is applied to the wet surface

• The mold is allowed to dry, and the process is repeated a number of times until a layered (or laminated) ceramic mold, capable to undergo the stresses of the casting process, has been built.

4. Dewax / Burnout

• Before pouring metal into the mold, the wax is removed• This is typically done using a steam-dewax autoclave, which is like a large, industrial pressure cooker

• Another method is the use of a flash fire oven, which melts and burns off the wax

• Many foundries use both methods in concert

• Autoclave removes the majority of the wax, which can be reconditioned and reused

• Flash fire burns off residual wax and cures the shell, readying it for casting.

5. Metal Pouring

• Before the metal is poured into the ceramic mold or “shell”, the mold is preheated to a specific temperature to prevent the molten alloy from solidifying or “freezing off” before the entire mold is filled• Alloy is melted in a ceramic cup (called a crucible) using a process known as induction melting

• A high-frequency electric current creates a magnetic field around the alloy, generating electric fields inside the metal (eddy currents)

• The eddy currents heat the alloy due to the material’s electrical resistance • When the alloy reaches its specified temperature, it is poured into the mold, and the mold is allowed to cool.

6. Shell Knock Off

• Once cool, the shell material is removed from the metal• This is typically done via mechanical means

• Hammer

• High-Pressure Water Blast

• Vibratory Table

• Shell removal can also be accomplished chemically, using a heated caustic solution of either potassium hydroxide or sodium hydroxide, but this approach is being phased out due to environmental and health concerns.

7. Cut Off

• Once the shell material has been removed, the parts are cut off the sprue and the gates are ground off• Part cut off can be done manually

• Chop saw • Torch

• Laser (limited applications)

• Parts can also be cut off using automation, that is, the mold can be secured using a fixture on a programmable cut off saw.

8. Individual Castings

• Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means• Vibratory/Media finishing

• Belting or hand grinding

• Polishing

• Finishing can be done by hand, but in many cases it is automated

• Parts are then inspected, marked (if required), packaged and shipped

• Depending on the application, the parts can be used in their “net shape” or undergo machining for precision mating surfaces.

Advantages and Disadvantages of Investment Casting Process

Advantages

Excellent surface finishHigh dimensional accuracy

Extremely intricate parts are castable

Almost any metal can be cast

No flash or parting lines

1. Excellent surface finish: The ceramic shell used is built around smooth patterns produced by injecting wax into a polished aluminum die. A 125 micro finish is standard, and even finer finishes are not uncommon.

Investment castings contain no parting line because only one mold is used rather than two half molds (such as in the case of sand casting). Standards for surface blemishes and cosmetics are discussed and agreed upon with the customer based on the function.

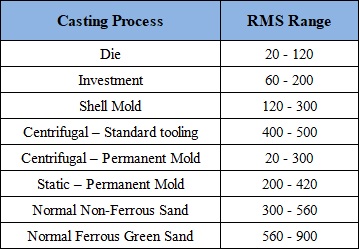

Below is a comparison of relative surface finishes that can be expected from various casting process:

The design phase can result in a drawing that reduces or even eliminates previous machining requirements to produce the same part.

The cost of any part increases in proportion to the preciseness of its dimensional requirements. Whether if it's castings machined parts or fabrications. A close design review will permit modification to tolerances, undercuts, blind holes, etc. to allow higher production yields and lower piece costs. If closer than cast tolerances are necessary, the machining required for investment casting will be less than conventional castings or fabricated components.

3.Extremely intricate parts are castable: Although most investment castings are small, the investment process can produce castings weighing more than 1,000 pounds. This capability is limited to a relatively small number of investment casters and requires special expertise in handling. Most cast parts fall in the ounces to a 20-pound range.

Investment casting provides consistent and repetitive close tolerances along with intricate passages and contours. Many of these configurations are impossible to produce. For example, where machine tools cannot reach. Achieving net-shape or near-net-shape cast components can dramatically reduce post-cast processing costs.

Investment casting is a good alternative to weldments or fabricating. Many components can be combined into a single casting. The more that are combined, the better the manufacturing efficiency. Converting multi-piece components to a single investment casting typically delivers more dimensional accuracy and reduced part complexity.

4.Almost any metal can be cast: Investment casting is used with almost any castable metal. However, aluminum alloys, copper alloys, and steel are the most common.

5.No flash or parting lines: Casting integrity is an important feature of the process. Investment casting has a long history of serving demanding sectors such as gas turbine engine, petroleum, chemical, defense, and medical.

Disadvantages

The main disadvantage is the overall cost, especially for short-run productions. Some of the reasons for the high cost include specialized equipment, costly refractories, and binders, many operations to make a mold, a lot of labor is needed and occasional minute defects occur. However, the cost is still less than producing the same part by machining from bar stock; for example, gun manufacturing has moved to investment casting to lower costs of producing pistols.Additionally:

It can be difficult to cast objects requiring cores.

This process is expensive, is usually limited to small casting, and presents some difficulties where cores are involved.

Holes cannot be smaller than 1/16 in. (1.6 mm) and should be no deeper than about 1.5 times the diameter.

Investment castings require longer production cycles compared to other casting processes.

The application of Investment Casting

Investment casting is used in the aerospace and power generation industries to produce turbine blades with complex shapes or cooling systems. Blades produced by investment casting can include single-crystal (SX), directionally solidified (DS), or conventional equiaxed blades.

Investment casting is also widely used by firearms manufacturers to fabricate firearm receivers, triggers, hammers, and other precision parts at low cost.Karsten Solheim famously revolutionized golf club design through his company PING by incorporating investment casting for the first time for clubheads. Quickly the process became an industry standard to allow weight distribution around the perimeter of the clubhead.

Other industries that use standard investment-cast parts include military, medical, commercial and automotive.

With the increased availability of higher-resolution 3D printers, 3D printing has begun to be used to make much larger sacrificial molds used in investment casting. Planetary Resources has used the technique to print the mold for a new small satellite, which is then dipped in ceramic to form the investment cast for a titanium space bus with an integral propellant tank and embedded cable routing.

Investment Casting VS Die Casting

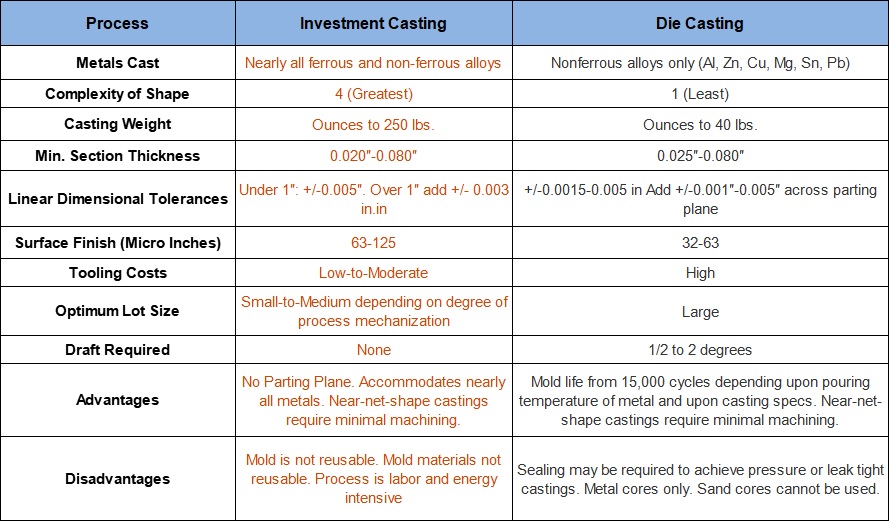

Comparison of Investment Casting VS Die Casting

Which process is right for my project?

No two casting projects are the same and with different projects, there are different solutions. Here are a few things to consider before you start your next project to help you choose which process is right for your component.

1. Material Selection

Most die cast parts are made from non-ferrous metals like zinc, aluminum, and magnesium. Investment casting is capable of casting cast those metals along with ferrous metals, including stainless steel. If you are looking to use a non-ferrous material, both processes offer comparable features. However, if you are looking to use stainless steel or copper alloys, investment casting is the better option.2. Annual Volume

When deciding which casting process to use, decide what your desired payback period is for the tool cost. How many parts created versus the cost of the tooling to “break even.” While investment casting tooling may be cheaper and suitable for lower volume projects, die casting is ideal for larger production runs and high-volume projects.3. Tolerance

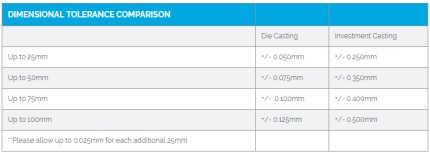

With any casting process, tolerance capabilities are largely influenced by the shape of the part and the type of material used. The table below compares general linear tolerances for conventional die casting and investment casting. The multi-slide die casting process is capable of holding even tighter tolerances.

4. Cycle Time

While investment casting and die casting both produce complex parts, the cycle times differ greatly. Traditional investment casting is a timely process that requires quite a bit of labor and hours of work, while die casting can produce 3-4 shots per minute for conventional die casting and upwards of 45 shots per minute with multi-slide die casting. A die-cast part can oftentimes be created without the touch of a human hand—complete automation!

5. Cost

Cycle time determines up to 60% of your final part cost so it is no surprise here, that per part, investment casting generally costs more than die casting. Its highly manual processes yield parts very similar to that of a die casting, but the cycle time is much longer.When casting in high volume, die casting is more cost-effective than investment casting. If you are casting only a few parts or require larger size or stainless steel, investment casting may be the lower-cost option.

Investment Casting VS Sand Casting

Sand casting and investment casting are methods of creating metal parts by pouring molten metal into three-dimensional molds. Although methods are thousands of years old, both have been refined over the years to minimize the amount of metal used and reduce any extensive machining and finishing required. But significant differences exist between these two methods of making metal parts. Below are some aspects you should take into consideration before choosing the right process.1. Design

In the investment casting process, the design can be made almost any shape. Investment casting design has extraordinary freedom to add intricate features and complex shapes. For sand casting parts, they usually have to be tapered (with draft angles) or shaped. It’s also a challenge for sand casting to make parts with internal voids or cavities. Sometimes, several cores may be needed. So sand casting design is limited by sand casting technology.

2. Materials

The investment casting raw material was to join the polyethylene material of paraffin wax, sodium silicate, silicon sol, whose costs are higher than foundry sand. Sand casting raw materials are clay sand or chemical self-hardening sand, the resources of the casting sand is rich and the price is cheap.

3. Casting Time

The investment casting mold process needs a longer period. Sand casting and resin sand is low. The molding cycle is short and has high efficiency.

4. Appearance quality

The investment casting surface is higher than the general casting, usually ranging from Ra.3.2 ~ 12.5μm. The surface of the sand casting is easy to be caused by the sand inclusion, sand wash, clip sand, air hole and other casting defects.

5. Dimensional Tolerance

Investment castings have very high dimensional tolerance, normally could reach CT 4-6. Sand castings have lower dimensional tolerance, size accuracy for CT10 ~ 13, the wall thickness of sand castings is a minimum of 3 to 5 mm.

6. Mass Production

The investment casting technology can ensure the consistency of the castings. But sand casting process is difficult to ensure the consistency of the castings. Unless by using molding machines, automatic molding lines or shell molding process.

7. Products Range

In China, investment casting is generally used to produce steel castings. It is generally used to produce small castings with unit weight under 20 kgs. Sand casting can be used for the production of cast iron and steel castings, and cast aluminum parts. The adaptability of the sand casting is very broad, small, large, simple, complex, single, large quantities can also be adopted.