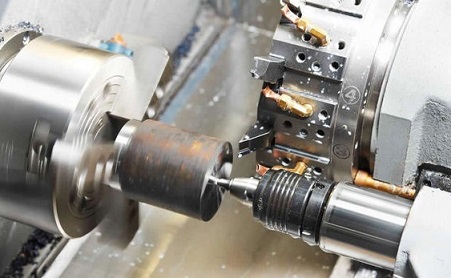

What are CNC clamping methods of the workpiece in the turning process?

Clamping the workpiece means positioning and clamping the workpiece on the CNC lathe or fixture. In the turning process, the workpiece must rotate along with the spindle of the CNC lathe. Therefore, when the clamping on the CNC lathe is required, the axis of the workpiece to be machined and the CNC lathe The axis of the main shaft must be coaxial, and the workpiece should be clamped to avoid loose or falling off the workpiece under the action of cutting force, resulting in an accident.

Depending on the shape, size and number of workpieces, different clamping methods can be used to clamp the workpiece on a CNC lathe. The accessories used in CNC lathes are the same as self-centering chucks/single-acting chucks, tops, mandrels, center frames, tool holders, faceplates and angle irons.1. CNC lathe self-centering chuck clamping work

The self-centering chuck of the CNC lathe is mounted on the spindle through a flange for clamping the workpiece. The square head wrench is inserted into the square hole of the self-centering chuck to rotate, the small bevel gear rotates, and the large bevel gear that drives the mesh rotates, and the large bevel gear drives the three claws which are threadedly engaged with the plane of the disk on the back side to move synchronously in the radial direction.

The self-centering chuck of the CNC lathe is characterized by three-claw automatic centering, simple clamping and correction of the workpiece, but the clamping force is small, and it is not possible to clamp large workpieces and irregular workpieces.The method of self-centering chuck loading and processing parts of the numerical control lathe has the methods of grasping and anti-clamping the workpiece. When the anti-clamping clamp is used, the three-catch is removed, and the jumper installation can reversely clamp the larger-diameter workpiece.

The jaws of the collet are called hard claws, which are hardened and hard. The claws made of non-quenched steel or copper-aluminum are called soft claws. They are generally welded on the hard claws. They are positioned well, and it is not easy to pinch the workpiece. It must be processed before use, and the car or the mill can be used.

2. CNC car bed sheet moving chuck clamping workpiece

The four claws of the CNC car bed moving chuck can be moved independently, because the back of each claw has a half-petal internal thread to mesh with the screw, the screwThere is a hole in the end. When a certain hole is rotated by a chuck wrench, the corresponding screw is rotated to clamp or loosen the claw. Therefore, the CNC car bed moving chuck can hold a square/rectangular/elliptical shape and an irregularly shaped workpiece, and can also turn the eccentric shaft and the hole. Therefore, the clamping force of the CNC car bed moving chuck is longer than that of the custom new chuck, which is used to clamp a normal circular workpiece with a larger diameter.

CNC lathes use a single-action chuck to clamp the workpiece. Because the four-jaw is not synchronized, it cannot be self-centered. It needs to be carefully aligned so that the axis of the workpiece is aligned with the axis of rotation of the spindle. The stencil is used to align the surface of the workpiece with the outer surface of the workpiece or the pre-marked processing line. The positioning accuracy is 0.2-0. 5mm; Positioning accuracy.

When the machining allowance of each part of the workpiece is not uniform, it is necessary to focus on finding a part with a small margin, otherwise it is easy to scrap the workpiece.

The CNC car sheet moving chuck can be used to grab or reverse the clamping of the workpiece. It can also be used with one or two anti-catch, and the rest still use the clamping device.

Deshengrui Machinery provide professional CNC turning service. We have high quality CNC lathe. As the company grow, we can make different kinds CNC turning parts, milling parts.