In technical communication, many people are accustomed to using the “surface finish” indicator. In fact, “surface finish” is proposed according to the human visual point of view, while “surface roughness” is proposed according to the actual microscopic geometry of the surface.

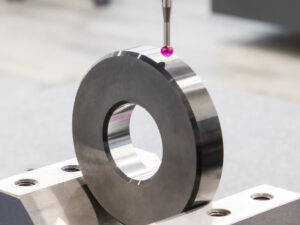

Surface roughness refers to the unevenness of small pitches and tiny peaks and valleys that a machined surface has. The distance (wave distance) between the two peaks or two troughs is very small (below 1mm), which belongs to the microscopic geometric shape error.

Specifically, it refers to the degree of height and distance S of tiny peaks and valleys. Generally divided by S:

S<1mm is the surface roughness

1≤S≤10mm is waviness

S>10mm is f shape

Surface Roughness Forming Factors

Surface roughness is generally formed by the processing method used and other factors, such as the friction between the tool and the surface of the part during processing, the plastic deformation of the surface layer metal when the chips are separated, and the high frequency vibration in the process system, electrical machining discharge pits, etc. Due to the different processing methods and workpiece materials, the depth, density, shape and texture of the traces left on the processed surface are different.

Surface roughness evaluation basis

1) Sampling length

The unit length of each parameter, the sampling length is the length of a reference line specified for evaluating the surface roughness.

2) Evaluation length

Consists of N reference lengths. The surface roughness of each part of the surface of the part cannot truly reflect the real parameters of the roughness on a reference length, but it is necessary to take N sampling lengths to evaluate the surface roughness.

3) Baseline

The reference line is the center line of the profile used to evaluate the surface roughness parameters.

Surface Roughness Evaluation Parameters

1) Height characteristic parameters

Ra profile arithmetic mean deviation: the arithmetic mean of the absolute value of the profile deviation within the sampling length (lr). In actual measurement, the more the number of measurement points, the more accurate Ra is.

Rz profile maximum height: distance between profile peak line and valley bottom line

Ra is preferred in the usual range of amplitude parameters. In the national standard before 2006, there was another evaluation parameter, which was “the ten-point height of micro-roughness” expressed by Rz, and the maximum height of the profile was expressed by Ry. After 2006, the national standard canceled the ten-point height of micro-roughness, and Rz was used. Indicates the maximum height of the profile.

2) Spacing feature parameters

Rsm Average width of contour elements. Within the sampling length, the average value of the distance between the microscopic irregularities of the profile. The micro-roughness spacing refers to the length of the profile peak and the adjacent profile valley on the center line. In the case of the same Ra value, the Rsm value is not necessarily the same, so the reflected texture will be different. Surfaces that pay attention to texture usually pay attention to the two indicators of Ra and Rsm.

The Rmr shape feature parameter is represented by the contour support length ratio, which is the ratio of the contour support length to the sampling length. The profile support length is the sum of the lengths of the section lines obtained by intersecting the profile with a straight line parallel to the midline and a distance of c from the profile peak line within the sampling length.

Hope the above content can help you!