What is 3+2 positioning processing

When a three-axis milling program is executed, the two rotary axes of the five-axis machine are used to hold the cutting tool in a tilted position. This is where the name 3+2 machining technology comes from. This is also called positioning five-axis machines because The fourth and fifth axes are used to orient the tool in a fixed position, rather than continuously during machining.

The principle of 3+2 positioning machining is essentially the realization of the three-axis function at a specific angle (that is, “positioning”). Simply put, when the machine tool rotates the angle, it is still processed in the ordinary three-axis manner.

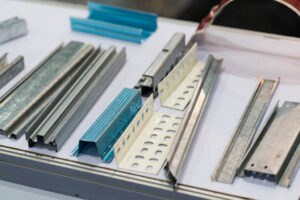

Now the commonly used machining centers on the market are mostly vertical machining centers, among which three-axis is the common way. The three-axis machining center is composed of linear feed axes X, Y, and Z. Generally, the direction of the cutting tool remains unchanged during the movement along the entire cutting path. In different processing strokes, different machine models are created.

Although the three-axis machining center has the advantages of high precision and high efficiency, it is more troublesome when machining complex workpieces with different surfaces. Because the length of the tool is too long, it is necessary to carry out multiple process increases and multiple clamping. At the same time, repeated tool setting produces cumulative tolerances, and easy overcuts will also cause unqualified workpieces. Therefore, multi-axis linkage machining has become the main choice when machining more complex workpieces.

3+2 axis technology is not a true five-axis horizontal machining center. Many friends think that the five-axis machining center is based on the three-axis machining center, adding two rotating axes. The two rotating axes first fix the cutting tool at an inclined position, and then process by the feed axes X, Y, and Z. . Since the fourth axis and the fifth axis are used to determine the direction of the tool in a fixed position, rather than running continuously during the machining process. Therefore, this is not a real five-axis linkage technology. The 3+2-axis machining center can meet the processing operations that ordinary machining centers cannot complete, but it is not a real five-axis machining center.

What is 5-axis simultaneous machining

According to ISO regulations, when describing the movement of CNC machine tools, a left-handed Cartesian coordinate system is used; the coordinate axis parallel to the main axis is defined as the Z axis, and the rotation coordinates around the X, Y, and Z axes are A, B, and C, respectively. Usually five-axis linkage refers to the linear interpolation motion of any 5 coordinates in X, Y, Z, A, and B.

The remarkable feature of the five-axis machining center is that it can complete curved surface processing, and no special fixtures are needed during processing, which greatly reduces the number of fixtures used. The real five-axis machining center is equipped with tool point follow-RPTC, which can better complete five-axis linkage machining. For a five-axis machining center with RTCP function, the tool center can always be kept at the programmed position. In this case, the tool orientation can be optimized during the movement along the entire path, while the tool moves in a straight line. This maintains good cutting conditions throughout the entire path. When programming on a five-axis machining center, you don’t have to worry about machine motion and tool length, all you need to consider is the relative motion between the tool and workpiece. The rest of the job control system is complete.

The five-axis machining center can not only greatly reduce the labor intensity of the operator, but also save a lot of clamping process, reduce the use of fixtures, and reduce the cost of fixtures. It has incomparable advantages in the processing field of complex workpieces with different surfaces.

The difference between 3+2 positioning and 5-axis linkage

3+2 positioning machining and 5-axis linkage machining are suitable for different industries. 5-axis linkage machining is suitable for curved surface machining, and 3+2 positioning machining is suitable for plane machining.

Advantages of 3+2 positioning processing:

1) Shorter, more rigid cutting tools can be used.

2) The tool can form a certain angle with the surface, and the spindle head can extend lower and get closer to the workpiece.

3) The tool movement distance is shorter and the program code is less.

Limitations of 3+2 positioning processing:

3+2 positioning machining is usually considered to set a constant angle to the main axis. Complex workpieces may require many oblique views to cover the entire workpiece, but this can cause overlapping toolpaths and increase machining time.

Advantages of 5-axis simultaneous machining:

1) There is no need for special fixtures during processing, which reduces the cost of fixtures, avoids multiple clamping, and improves mold processing accuracy.

2) Reduce the number of fixtures used.

3) Many special tools are omitted in processing, thereby reducing tool costs.

4) During processing, the effective cutting edge length of the tool can be increased, the cutting force can be reduced, the service life of the tool can be improved, and the cost can be reduced.

Limitations of 5-axis linkage:

1) Compared with 3+2 positioning, its spindle rigidity is worse.

2) In some cases, the five-axis solution is not suitable, such as the tool is too short, or the tool handle is too large, so that vibration cannot be avoided under any inclination angle.

Compared with 3-axis machine tools, the machining accuracy error is large.

Hope the above content can help you!