Gears were probably one of the earliest materials used by humans. They are found in almost all modern machinery. To withstand harsh operating environments, gears must be well-manufactured, reliable, efficient and durable. Gears must be reduced in stress and strain to avoid failure, which can lead to conditions. To meet all these needs, gear manufacturing has developed into a highly specialized industry.

Depending on the parameters, different materials can be used to manufacture the gears. While non-ferrous materials such as plastics and composites are used in some applications, steel is the most commonly used material in others.

Gears are typically made from steel (the most common material) and a variety of non-ferrous materials including plastics and composites. According to the design requirements, the gear material should have the following properties: high tensile strength under static load, high durable strength under dynamic load, low coefficient of friction, and good manufacturability.

Gears can be manufactured using various methods including casting, forging, extrusion, powder metallurgy and stamping. Among them, machining is the most commonly used production method.

Cutting

Common cutting operations include: gear hobbing, gear shaping, rack planing, gear cutting with disc milling cutters, and broaching.

Electrical Discharge Machining (EDM)

EDM is a manufacturing process that removes material from a workpiece by applying a series of electrical discharges between two electrodes separated by a dielectric bath.

EDM excels at cutting complex geometries of all sizes, but has its limitations. If you don’t have good control and procedures, it’s easy to damage part surfaces, especially tooth profiles that are challenging for CNC programs to execute. But high-quality and intuitive 3D modeling and CAM software, such as Feature CAM, Autodesk Fusion, Master CAM, etc., can produce the smooth motion needed to cut helical teeth.

EDM machines have improved in recent years. Early EDM machines and this process had limitations, but they have continued to evolve. This evolution addresses issues of maximizing surface finish, improving cutting accuracy and resulting material properties (microstructure, mechanical properties, etc.). The process can achieve tolerances accurate to one-thousandth of an inch, and can produce small gears (less than 2 mm in diameter) and large gears (over 600 mm in diameter). The process is used both for precision applications in timepieces and for cutting stronger gears, such as those used in racing cars.

Rolling

Rolling is one of the oldest forming processes. It forms gears by hot or cold rolling a blank workpiece through two or three dies.

How to save material is a key issue in the manufacturing process, and rolling is a good choice because no chips will be produced. However, for an efficient process, you must consider rolling parameters, deformation and microstructural effects before increasing throughput.

Casting

Casting is a forming process used to manufacture gear blanks (which are then machined) and complete gears with cast tooth profiles. Tolerance and precision are key considerations when casting gears, and creating the molds requires significant upfront costs. However, once the tooling and process parameters are established, high-volume production justifies the investment.

Sand casting is mainly used to produce gear blanks for other processes. Fully functional spur gears, helical worm gears, and bevel gears are all cast from gears and are used in washing machines, small appliances, hand tools, toys, and cameras.

Powder metallurgy

Powder metallurgy is a high-precision forming method that is a cost-effective alternative to conventional machining of steel and cast iron gears. However, this method is not suitable for larger gear sizes, but is good at making small, high-quality spur, bevel and helical gears. Larger gears have lower fatigue and impact resistance due to the porosity of the molded material, although sintering processes can be used to improve their mechanical properties.

Powder metallurgy is also particularly useful when the gear design includes holes, depressions and different surface levels or protrusions. You’ll find these gears in appliances, farm, lawn and garden equipment, cars, trucks and military vehicles.

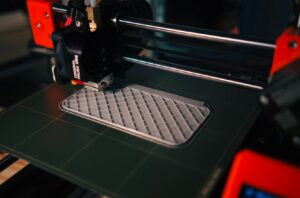

Additive manufacturing

Additive manufacturing, also known as 3D printing, builds three-dimensional objects layer by layer from a CAD 3D model. Due to the nature of the process, additive machines can form complex designs with lattice structures. These structures can be modeled to achieve lightweights not easily attainable through traditional methods. This type of geometry is often created using 3D topology optimization and computer design software.

Both conventional and non-circular gears can be fabricated through additive manufacturing processes, and high-quality 3D printers are relatively inexpensive and widely available. Because of this availability, it has become the choice for repairs and mechanical projects, such as educational toys or other gadgets that require fully functional gear. You can also include other features and even combine geometry with gear shapes to add custom shafts, keys or grooves into the same entity.

As you can see, there are many ways to make gears. Hope this article can help you.